Notark R Series resins are precision engineered reactive polymer systems developed to elevate the performance of next-generation electronic materials. At their core is a dendritic architecture composed of reactive, low-polarity monomers. This structure strikes an optimal balance between processability and mechanical strength, while the tailored monomer selection imparts outstanding dielectric, thermal, and mechanical properties. The resulting Notark R series resins deliver exceptional signal integrity and material stability in high-speed, high-frequency applications.

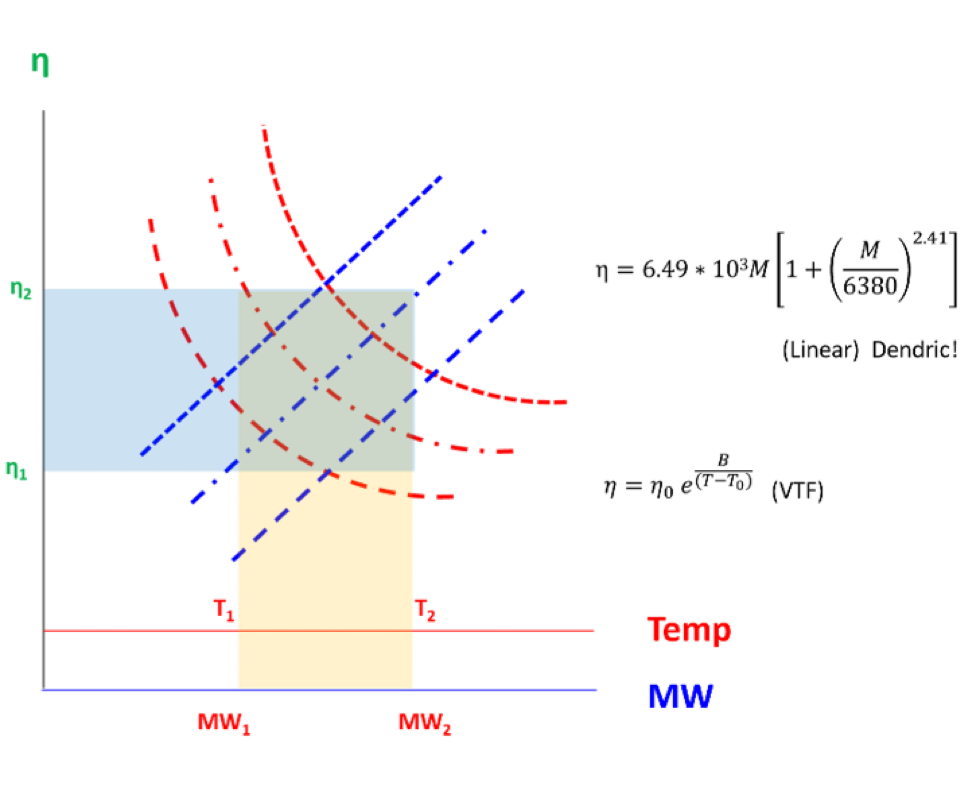

Notark R-series resins feature a dendritic architecture that enables exceptional solution and melt rheology, while preserving high reactivity for robust thermoset formation. Our proprietary chemistry and manufacturing process provide a wide design window in both composition and molecular size, allowing precise control over viscosity and flow behavior. Tailored resin composition adjusts reactivity and crosslink density, forming a strong 3D network upon cure. At the same time, molecular size tuning offers control over melt flow and strength – critical for processing efficiency and end-use reliability.

With a deep understanding of the interplay between molecular size, building block composition, melt behavior, and curing kinetics, Notark delivers customized resin solutions designed to meet each customer’s specific formulation and manufacturing requirements.

Glass transition temperature (Tg) of 210 °C to 240 °C

Dissipation factor (Df) of 0.00045 to 0.00070 at 10 GHz frequency

Dielectric constant (Dk) of 2.45 to 2.55 at 10 GHz frequency

Coefficient of Thermal Expansion (CTE) of 8 to 20 ppm/oC (X-Y direction); < 2 % (Z direction) in glass fabric laminate

Excellent peel strength > 0.6 N/mm (> 3 lb/in) to copper foil

Extremely low moisture absorption of 0.036%

Good solubility in Toluene, MEK, Xylene, Cyclohexane

Highly reactive resin that forms tight 3-D network without the use of peroxides or other crosslinking agents

Excellent processability in existing CCL process infrastructure

| Analysis Parameter | Unit | Typical Value |

|---|---|---|

| Total Solids | % | 55 – 65 |

| Viscosity, Brookfield @ 25 °C (18 SS) | cPs | 20 – 1,200 |

| Grit (Retained on 2485 mesh / 5 µm) | ppm | < 50 |

| Moisture (Coulometric KF) | ppm | < 20 |

| Color Appearance (Hunter Gardner) | – | < 0.8 |

| Metal ion residuals (ICP-OES)* | ppm | < 1 ppm |

| Appearance of toluene solution | – | Clear |

Let us discuss how our technology can optimize your products.